30%

non-energetic material can be handled by the process, including metals, glass, and rocks.

6X

less electric power needed than with electrolysis, as most of the energy driving the process is in the waste.

$300 Million

deployed to date in technology development by our partner Omni Conversion Technologies.

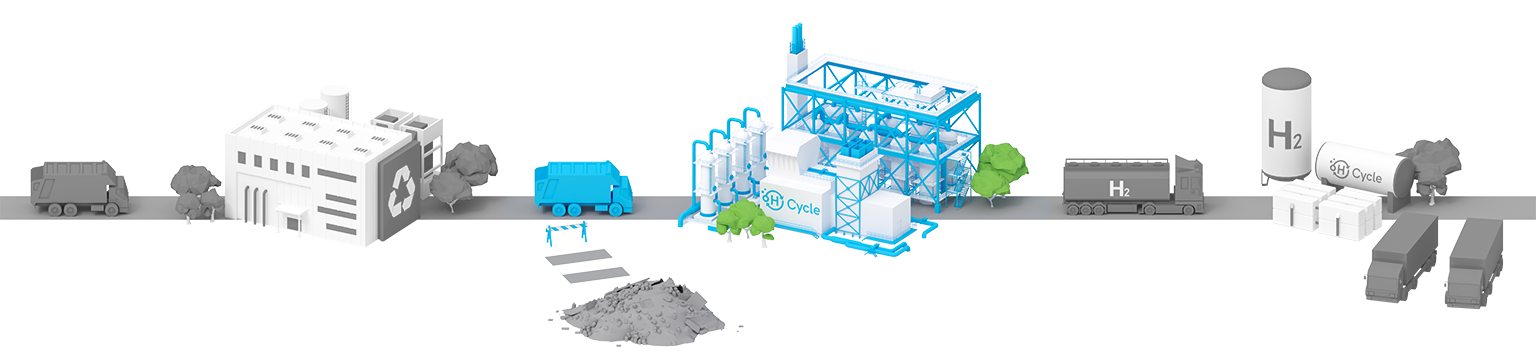

How the process works

Our technology is a thermal process that uses heat and electricity to transform waste into hydrogen along with a few safe, easily managed products and minimal emissions.

- Recycle what is recyclable.

- Divert local communities’ unrecyclable waste otherwise headed to the landfill.

- Extract energy in the form of a hydrogen-rich gas (known as synthesis gas) from solid waste.

- Capture CO2 that can be be made ready for sequestration (optional), transforming waste disposal into a carbon-negative solution.

- Purify and deliver hydrogen to decarbonize refining, industrial uses, and heavy-duty fleet fueling.

Benefits of our process

-

Best-in-Class Technology

H Cycle has secured the exclusive right to deploy a proven-at-scale, world-class thermal conversion technology in premiere markets.

-

High Energy Efficiency

The process utilizes a limited amount of external power and energy, as most of the energy driving the process is in the waste itself.

-

Process Flexibility

The H Cycle process is capable of handling highly mixed and variable feedstock by introducing several steps in the process to improve flexibility and control of key process parameters.

-

Low Emissions

The advanced conversion utilized results in a very low emission process (minor source), with no dioxins and furans, while producing a non-leachable slag byproduct that seals metals and ash into a reusable form.